|

|

|

|

|

| For more information follow these links. |

|

|

|

|

|

|

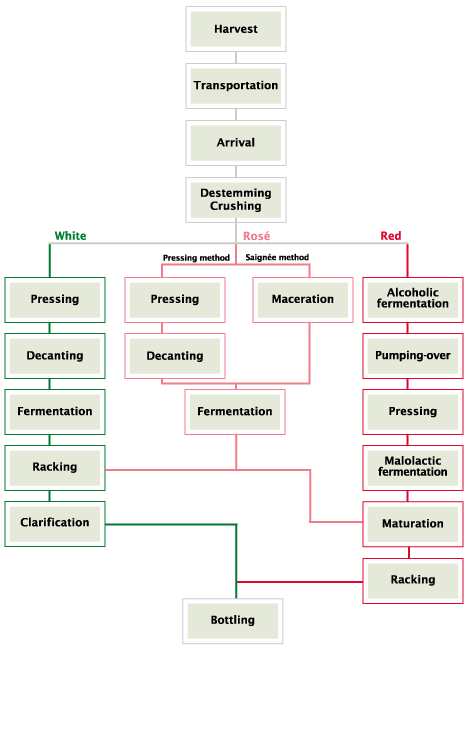

In the production of still wines, grape juice is transformed into wine through fermentation. If wine is produced through fermentation off skins, peeled and slightly smashed grapes are used. This method is used for white and rosé wines made from the white method. If, on the other hand, it is important to maintain the grapes’ pigments and tannins, the wine is produced through fermentation on skins (common in reds and rosés made from the red method).

|

|

|

Harvest

The harvest is the first step in winemaking. After that, the grapes are taken to the winery and subject to the necessary transformation processes. Since the production of white wine differs from that of the red, the oenological practices will depend on the colour of the grapes. |

|

|

|

|

Transportation

When they get to the winery, the grapes should be undamaged and in the best possible hygiene conditions. Transportation should not crush the grapes: harvesting is done under hot weather and, if the grapes are not intact, the fermentation process may begin earlier than it should. |

|

|

|

|

Arrival

Once arrived at the winery, the grapes go through a quality control process. After being selected, they are unloaded to the receiving bin (a big container in the shape of an inverted pyramid) and get a sulphur dioxide treatment, which prevents the grapes from quickly oxidising. At this point, it is possible to perform other oenological practices. After that, the grapes are taken to the crusher-destemmer. |

|

|

|

|

Destemming | Crushing

Destemming is the process of totally or partially removing the stems from the grapes. In

the production of white or rosé wines, total destemming is usually used. Afterwards, the grapes may or not be crushed. Crushing splits the grapes’ skin to release the pulp and juice. When done manually, the process may split the skin or simply crack it. When done mechanically, crushing depends on the distance between the machine’s rolls (the smaller the distance, the greater the crushing).

|

|

|

|

|

Pressing

Pressing is the process by which one gets the must out of the grapes. A press extracts the grapes’ juice and releases their skins. This process must be conducted very carefully so as not to release acidity from the seeds and skins. The act of separating the must from the solid part is characteristic of white wines and is called fermentation off skins. |

|

|

|

|

Decanting

This process takes a day or two and consists of letting the solid parts resultant from pressing form a deposit at the bottom of the tank, for further elimination. Only the must will be fermented. Lees (suspended solids) make winemaking harder and may impart unwanted flavours to wine, hence the importance of removing them. |

|

|

|

|

Fermentation

The must is transferred to stainless steel, cement or fibreglass tanks, where it is fermented for 15 to 20 days. There, yeast converts the grapes’ sugar into alcohol and, at the end, the must turns into wine. Must itself has yeast capable of initiating the fermentation process, but in quality wines it is usual to add selected yeasts, whose activity produces some controlled effects. Stainless steel tanks allow a better control of the fermentation temperature (ideally between 14º and 18ºC), which helps preserve the wine’s aromas and freshness. Some white wines may go through an ageing or even fermentation process in wooden casks. |

|

|

|

|

Racking

In this process, the wine is transferred to a clean tank and the remaining particles, such as lees at the bottom of the tank, are extracted. A small quantity of sulphur dioxide (SO2) may be added to the wine, in order to preserve and protect it from oxidation. Topping up is another common operation and consists in filling the tank with wine, usually from the same quality. |

|

|

|

|

Clarification

Clarification is a process that eliminates all impurities in suspension in the wine and renders it clear. There are two techniques for clarifying wine: fining and filtering. Fining involves the addition of a clarifying product (such as gelatine, bentonite [clay], etc.) to the wine. The product coagulates, forming sediments. These sediments attract and drag impurities. In the second technique, the wine is passed through a filter that retains the suspended particles and impurities. It is important to mention that there is also a natural clarification method, called bâtonnage. It periodically removes yeast from the bottom of the container in which fermentation occurs, but may take several months to do so. |

|

|

|

|

Alcoholic fermentation

Red wine is made through fermentation on skins, which means the fermenting must is in contact with the solid parts of the bunches (seeds, skins, and sometimes even stems). The grapes are taken to stainless steel, cement or wooden fermentation tanks. Yeast converts grapes’ sugar into alcohol and carbon dioxide. This last one makes the must’s solid parts go up to the surface. During fermentation it is possible to remove parts of the must, in order for the final product to be more concentrated. |

|

|

|

|

Pumping-Over

Since the grapes’ solid parts have a tendency to go up to the surface, it is necessary to mix them with the liquid at the bottom of the fermentation tanks. This is done with the help of a pumping system that makes the liquid circulate and mix with the solid parts. The advantages of pumping-over are, among others, the homogeneous distribution of yeast and temperature. |

|

|

|

|

Pressing

Pressing of red wines usually occurs at the end of fermentation. The grapes are crushed to release liquid from the berries. Pressing should be performed at the right time; otherwise the wine will leave an unpleasant taste in the mouth. Unlike white wines, red wines are pressed after fermentation. This happens because the grapes’ skins and seeds should be in contact with the must to impart colour and other properties to it. |

|

|

|

|

Malolactic fermentation

Malolactic fermentation is the conversion, by bacteria, of malic acid into lactic acid. The less ripe the harvest, the more intense malic acid is. A distinguishing characteristic of malic acid is its aroma (resembling green apples). Malolactic fermentation makes a great part of the wine’s acidity disappear. |

|

|

|

|

Maturation

Red wines can be aged in barrel or oak. Ageing allows the wine to stay in contact with some air and get “wooded” characteristics. Young oak (Portuguese, French or American) gives more intense tannins and a vanilla flavour. Old oak, on the other hand, has an oxidising effect, enriching the wines’ complexity. |

|

|

|

|

Racking

As time goes by, the suspended particles form a deposit at the bottom of the cask. Thus, the wine has to be transferred to a clean tank. At this point, the wine can be blended (mixed with other grape varieties or wines). Next is the clarification (elimination of all impurities in suspension in the wine), though some reds may not be clarified, and stabilisation (biological stabilisation) processes. |

|

|

|

|

Pressing

In this process, the must suffers the action of a pneumatic press or automatic treading. This operation must be conducted carefully so as not to release too much acidity from the seeds and not to impart a too pinkish colour to the wine. Rosés obtained from this process have generally a light pink colour. |

|

|

|

|

Decanting

Suspended particles, little grape skins and other unwanted elements are removed. Only then the must is transferred to the fermentation tanks. |

|

|

|

|

Maceration

Usually, the must stays in contact with the grapes for a period of a couple of hours, but that can last for 3 days. The duration of this phase will have implications on the wine’s colour and tannins. Solid parts (skins and seeds) are separated from the must (grape juice) and it is taken to the fermentation tanks. Independently from using one method or the other (pressing or saignée), rosé wine will have more texture and a more intense flavour than a white wine, but less tannins than a red one. |

|

|

|

|

Fermentation

In fermentation tanks, sugar is converted into alcohol. The process is usually initiated using yeast. In rosé wines, fermentation temperatures are between 14º and 18ºC. The wine is then biologically treated and, usually, blended (combined with other wines to enrich the aromas and flavour). |

|

|

|

|

Bottling

Bottling consists of filling bottles with an exact quantity of wine. After bottling, one places the cork, label, capsule and quality seal. |

|

|

|

|

|